Ulysses Flight Computer: Difference between revisions

m →Rev 2.2 |

|||

| Line 15: | Line 15: | ||

It supports up to 2x SPI hardware channels, 2x I2C hardware channels 2x UART hardware channels and 4x ADC devices with 12 bits of resolution. It supports 48 GPIO pins with connection to 3 PIO blocks. | It supports up to 2x SPI hardware channels, 2x I2C hardware channels 2x UART hardware channels and 4x ADC devices with 12 bits of resolution. It supports 48 GPIO pins with connection to 3 PIO blocks. | ||

==== programming the controller ==== | ==== programming the controller with a .uf2 file ==== | ||

The Stamp XL has 2 buttons marked "reset" and "boot". In order to program the board | The Stamp XL has 2 buttons marked "reset" and "boot". In order to program the board it must be powered on from the off state while holding the "boot" button. | ||

Once on, the board will appear as an external storage (like a usb stick) on any externally connected computer trough usb. | |||

In this state it is possible to program the board by dragging the relevat ".uf2" file inside the fake external storage. As soon as the file upload will complete, the board will automatically reset and start with the program. At least one power reset is advisable afterward to ensure the board is in the correct state. | |||

=== Power Supply === | === Power Supply === | ||

| Line 23: | Line 27: | ||

===== expected Power usage ===== | ===== expected Power usage ===== | ||

While idle the board is expected to not consume any power. | |||

=== Sensors === | === Sensors === | ||

===== lis3mdl ===== | ===== lis3mdl ===== | ||

This is a 3-axis magnetometer from STMicroelectronics. | |||

===== lso6dso32 ===== | ===== lso6dso32 ===== | ||

This is a package with a 3-axis accelerometer and a 3-axis gyroscope. It is often referred as the "IMU", or "Inertial Reference Unit". | |||

===== bmp390 ===== | ===== bmp390 ===== | ||

This is a precision barometer | |||

=== Pyro Channels === | === Pyro Channels === | ||

| Line 54: | Line 62: | ||

The first revision suffered from multiple failures: | The first revision suffered from multiple failures: | ||

* Sensor pad were too small, with no consideration to the | * Sensor pad were too small, with no consideration to the solder mask or the pad dimension. Only the IMU's soldered correctly. | ||

* The Speaker had a unconnected pad, making it useless | * The Speaker had a unconnected pad, making it useless | ||

* The wrong footprint for the USB was used, resulting in the lack of the underlying hole | * The wrong footprint for the USB was used, resulting in the lack of the underlying hole | ||

| Line 65: | Line 73: | ||

==== Problems ==== | ==== Problems ==== | ||

* Sensor pad were still to small, resulting in low soldering | * Sensor pad were still to small, resulting in low soldering reliability. Every sensor soldered, but we could never get a single board with every sensor soldered | ||

* every NMOS had the gate and drain pin inverted | * every NMOS had the gate and drain pin inverted | ||

* we forgot to order the PMOS mosfet controlling the servo | * we forgot to order the PMOS mosfet controlling the servo | ||

| Line 74: | Line 82: | ||

=== Rev 2.2 === | === Rev 2.2 === | ||

Changes have been made from the rev 2.0 in order to comply to the [https://www.st.com/resource/en/technical_note/tn0018-surface-mounting-guidelines-for-mems-sensors-in-an-lga-package-stmicroelectronics.pdf TN0018] technical note from ST-Microelectronics on the sensor footprints. | |||

==== Soldered Boards ==== | ==== Soldered Boards ==== | ||

the n.5 was a complete assembly, lacking only the connectors. An over-application of solder paste resulted in a sensor failure and a short of the SPI bus. rework solved the short, but only one of the two IMU ended up working. The rest of the sensor pack failed to respond to SPI calls. Also a problem with the n-mos controlling the speaker was detected, creating a 250 mA load, and overheating the speaker. This has been solved removing the n-mos controlling the speaker. | the n.5 was a complete assembly, lacking only the connectors. An over-application of solder paste resulted in a sensor failure and a short of the SPI bus. rework solved the short, but only one of the two IMU ended up working. The rest of the sensor pack failed to respond to SPI calls. Also a problem with the n-mos controlling the speaker was detected, creating a 250 mA load, and overheating the speaker. This has been solved removing the n-mos controlling the speaker. | ||

Revision as of 21:22, 10 April 2025

Components

Controller

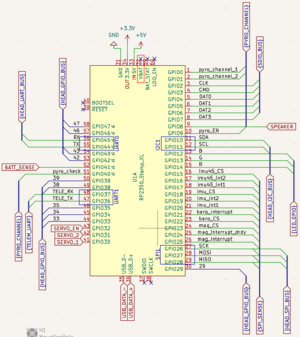

The board uses a RP2350 Stamp XL from solder party that, other than the micro-controller, mounts:

- 16 Mb of external FLASH

- 500 mA 3.3V LDO

- Footprints for external SWD and UART JST connectors

The Stamp has been chosen for the ease of mounting and for a lack of a commercially available RP2350 board / chip at the time of design. The main downside is the dimensions of the castellated board, which define the board layout.

The RP2350B is a dual core ARM-M33 or Hazard-3 RISV-V micro-controller with 520Kb of SRAM and 16 Mb of external FLASH memory. It has a flexible clock, varying from 150 MHz up to 200 MHz.

It supports up to 2x SPI hardware channels, 2x I2C hardware channels 2x UART hardware channels and 4x ADC devices with 12 bits of resolution. It supports 48 GPIO pins with connection to 3 PIO blocks.

programming the controller with a .uf2 file

The Stamp XL has 2 buttons marked "reset" and "boot". In order to program the board it must be powered on from the off state while holding the "boot" button.

Once on, the board will appear as an external storage (like a usb stick) on any externally connected computer trough usb.

In this state it is possible to program the board by dragging the relevat ".uf2" file inside the fake external storage. As soon as the file upload will complete, the board will automatically reset and start with the program. At least one power reset is advisable afterward to ensure the board is in the correct state.

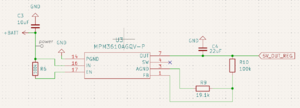

Power Supply

The Ulysses flight computer uses an MPM3610 switching regulator with a maximum load of 1.2 A. This converts the +BATT voltage down to +5V. The voltage is then lowered by the Stamp internal LDO down to +3.3V.

expected Power usage

While idle the board is expected to not consume any power.

Sensors

lis3mdl

This is a 3-axis magnetometer from STMicroelectronics.

lso6dso32

This is a package with a 3-axis accelerometer and a 3-axis gyroscope. It is often referred as the "IMU", or "Inertial Reference Unit".

bmp390

This is a precision barometer

Pyro Channels

I/O Ports & Connectors

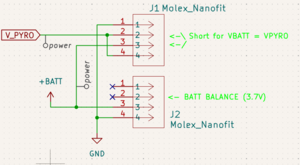

Molex Nanoftis

There are 3 Molex Nanofit connector, dedicated to the power management of the vechile and the connection to the Tracker:

- The Battery connector with connections to the battery lead

- The Pyro connector, which could be used to connect an external battery to use for the pyros or could be jumped to use the main battery. A specific connector should be made in order to jump the connector

- The Telemetry connector which brings the battery cables to the Tracker along side a UART connection. The telemetry has the pins already switched in respect of the main board, so no null modem cable is required

USB port

A USB type-c port is available on the side of the board. This may be blocked during assembly of the avionics bay. It is used for programming the board and recovering file in case of a filesystem in the FLASH memory.

History

Rev 1.0

Problems

The first revision suffered from multiple failures:

- Sensor pad were too small, with no consideration to the solder mask or the pad dimension. Only the IMU's soldered correctly.

- The Speaker had a unconnected pad, making it useless

- The wrong footprint for the USB was used, resulting in the lack of the underlying hole

Soldered Boards

we only soldered one, the id n.1. It now lives on the graveyard panel in the lab

Rev 2.0

Problems

- Sensor pad were still to small, resulting in low soldering reliability. Every sensor soldered, but we could never get a single board with every sensor soldered

- every NMOS had the gate and drain pin inverted

- we forgot to order the PMOS mosfet controlling the servo

- The Resistor packs filtering the SD channels had the wrong footprint, resulting inverted connections

Soldered Boards

we soldered 3 boards: id n.2,3,4

Rev 2.2

Changes have been made from the rev 2.0 in order to comply to the TN0018 technical note from ST-Microelectronics on the sensor footprints.

Soldered Boards

the n.5 was a complete assembly, lacking only the connectors. An over-application of solder paste resulted in a sensor failure and a short of the SPI bus. rework solved the short, but only one of the two IMU ended up working. The rest of the sensor pack failed to respond to SPI calls. Also a problem with the n-mos controlling the speaker was detected, creating a 250 mA load, and overheating the speaker. This has been solved removing the n-mos controlling the speaker.